06/29/2020

Crazy days. First there was an unidentified intruder that dug a two foot deep hole in the midst of the tomato plants. Then, while at the top of a twenty five foot ladder killing wasps, the wand blew out from the hose that was carrying high concentrations of commercial grade insecticide under 40 psi of line pressure. I ended up wearing most of the contents from the fifty gallon chemical tank attached to the tractor.

On the bright side, the tomato plants were not at all harmed by the midnight marauder and, I suspect, bodily absorption of highly toxic chemicals will probably render me bug free for the duration of the summer.

The Ruger Hawkeye African. The rifle that makes me smile…

I have no idea where the future of firearms lies, or even stands or sits in the future as my interest resides in the past. The Ruger Hawkeye, despite its very modern design refinements, improved materials, computer controlled precision machinery, and greatly enhanced manufacturing processes, is still a progression of the classic bolt action design. Even the walnut stock remains with improved geometry, capped and tipped with black ebony, clean checkering and classic blued alloy steel barreled action.

For the most part, factory rifles are shipped incomplete, specifically without a sight system. The Ruger Hawkeye, with its quality metallic sight set, can be taken to the range with a couple of boxes of factory ammo, sighted in, shot for proficiency, and then taken hunting.

Still, I like to fiddle with things…

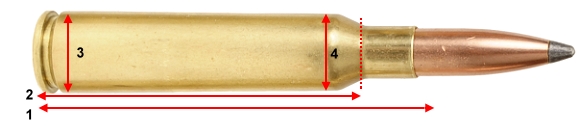

The 6.5×55 Swedish, with 57 grains of H2O capacity, is not a small cartridge. In fact, it has greater capacity than the 6.5 Creedmoor (54 grains) and 260 Remington (53 grains). Relatively sharp shoulders, and with a modest amount of body taper, the 6.5×55 Swede is quite a hot rod for an 1894 design.

What subordinates the cartridge to the others noted, is its low SAAMI MAP of 51,000 PSI compared to 62,000 PSI for the Creedmoor and 60,000 for the 260 Remington. There is no deficiency in the cartridge or the Ruger that warrants this low pressure level. It was created as a ceiling to assure safe operation in the 1894 Swedish military Mauser. Much of the data below increases pressure levels closer to the 58,000 to 60,000 level and is no suitable for use in older firearms, certainly not the pre 1900 Swedish Mauser.

I mentioned in a Facebook post that hundreds of rounds are required to develop safe and useful handloads for a single cartridge with range of bullets. For each bullet, there are tests for power types, then tests for charge levels, then tests for accuracy and then enough repetitions of each test must be run to substantiate results. The process may seem tedious but, in my view, it is essential. I don’t use data people send me, I don’t use social media sources and I am definitely the guy who really begins with minimum loads presented in a manual and then work up from there.

Sometimes old methods of determining excess pressure by chronograph readings, dimensional changes to brass and visual inspection for classic symptoms of excess pressure are employed. Sometimes pressure is checked with a strain gauge and sometimes with a universal receiver, test barrel and piezo transducer. The latter reserved for longer term cartridge load research and follow on production. In this case, it is more VFR than IFR navigation.

Closing note, it is true that social media, rifle with engineers, have proved beyond a shadow of a doubt that classic symptoms of high pressure are not valid; flat primers, hard extraction, excessive velocity, odd report, excessive case head diameter increases above the rim….. I am sure they are correct, but I can’t figure out why all of the major component manufacturers, the guys who design the pieces and carry the responsibility still include all of those classic symptoms in the trouble shooting section of their manuals and in their online presences.

All I know is that if you shoot enough rounds with pressure checking equipment or over a chronograph, and closely inspect fired casings, you will be able to hear, feel and probably smell excessive pressure and you will find that the old indicators are still very valid.

Some assembly required

I have long been an admirer of Joliet Jake Blues’s explanation to the Mystery Woman, as to why he was a no show at their wedding. Laying in a puddle, in a sewer, with Mystery Woman holding him at gun point, the end of a long pursuit, he looked up at her with schmutz on his face and a feigned look of innocence he said –

“I ran out of gas. I, I had a flat tire. I didn’t have enough money for cab fare. My tux didn’t come back from the cleaners. An old friend came in from out of town. Someone stole my car. There was an earthquake! A terrible flood! Locusts! IT WASN’T MY FAULT, I SWEAR TO GOD!”

In Part 1, I committed to generating original data for nine bullets for the 6.5×55 Swedish. So please see the preceding. Alternatively, I bit off more than I could chew in light of the project schedule and had to reduce the count to six. In context, the six selected are more suited to the Ruger Hawkeye African. The other three were specialized match bullets and not really applicable to a hunting rifle, even if an accurate hunting rifle…. I SWEAR TO GOD!.

| Bullet | Type | Grains Weight |

Length” | Cartridge Overall Length |

| Sierra Varminter | Flat Base Hollow Point | 100 | 0.935 | 2.850 |

| Sierra Pro-Hunter | Flat Base Soft Point | 120 | 1.080 | 3.000 |

| Nosler Partition | Flat Base H Jacket | 125 | 1.170 | 3.025 |

| Hornady Interlock SP | Flat Base Soft Point | 129 | 1.185 | 2.905 |

| Hornady SST | Boat Tail Poly Tip | 140 | 1.410 | 2.905 |

| Hornady ELD-X | Boat Tail Poly Tip | 143 | 1.435 | 3.025 |

The Sierra Varminter has been around since 1960. It is not a fragile bullet that will yield explosive results in small critters like woodchucks. In fact, Sierra recommends it in 0.264″ up through the 264 Winchester Magnum. For the 6.5×55 Swedish, it is effective on larger varmints like coyote. The bullet has a reputation for accuracy.

The Sierra Pro-Hunter is a good flat based, soft point, that does not rob powder capacity and it is definitely tough enough for medium size game like deer and hogs. Sierra recommends this bullet for long range work with the 264 Winchester Magnum and 6.5×284, but stipulate it is to fragile for close in work. For the 6.5×55 Swedish, it is about a perfect balance of toughness and controlled expansion for both close in an distance shots.

The Nosler Partition selected is the lighter of two Partition bullets offered in 0.264″ diameter. The other is 140 grains. In my experience, the tapered jacket, dual core construction holds up well is hunting situation. Even when pushed to magnum velocity levels, even if the nose gets a bit blown away by a too close shot, the tail end always holds together. For use with the 6.5×55 Swedish, it is another ideal balance of toughness and expansion.

The Hornady Interlock SP is another mature product, which puts it in the category of “If it ain’t broke…” An excellent single core bullet with a cannelure and internal ring that locks jacket to lead core. It works well on deer, hogs and black bear.

The Hornady SST is a longer range selection as the jacket and core are designed to promote full expansion at a distance, although Hornady’s bullet guide indicates a muzzle velocity between 1,500 and 3,200 fps. I suspect what matters more than muzzle velocity is impact velocity on game. Hornady recommends the bullet for medium and large game including elk and moose.

The Hornady ELD-X is intended to be a long range improvement over the SST and it has a more narrow recommended velocity range 2,000 to 3,200 fps muzzle velocity. It is also recommended for medium and large game. The extremely low drag is a significant benefit for long range shooters as you will see in the ballistic tables that follow handload data.

The 6.5×55 Swedish works well close up, as well as wayyy down range. Components and combinations for the handloader are widely available to accomplish either.

Even more minutia…

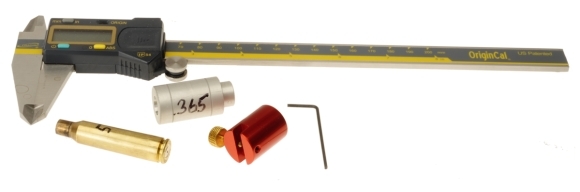

Norma brass was selected for snob appeal and because I like the alloy. Cases were once fired, cleaned and trimmed. Ammunition was full length resized and assembled without bullet crimping. Die manufacturer selections vary based on cartridge, intended use and frequency of use.

When I have a pet cartridge, I usually spoil it by buying Redding dies. Yes, I do use other brands, which are all terrific, but I have gotten the best results and longest use out of Redding dies. Maybe it’s that green box with all of the purposeless holes? Probably more of an appreciation for the design of the seater plug and decapping rod and associated method of adjustment and/or retention, the close dimensional control and the circular lock rings.

In this case, there are two sizing dies in the set, neck and full length, and one seater. I never use the neck sizing die, but it is there in the event I lose my mind and reverse everything I have done over the reloading entirety of my life.

And then prodigious shooting occurred…

Warning: Bullet selections are specific, and loads are not valid with substitutions of different bullets of the same weight. Variations in bullet length will alter net case capacity, pressure and velocity. Primer selection is specific and primer types are not interchangeable. These are maximum loads in my firearms and may be excessive in others. All loads should be reduced by 5% as a starting point for development where cartridges have greater than 40 grains in capacity and 10% for cartridges with less than 40 grain capacity following safe handloading practices as represented in established mainstream reloading manuals. Presentation of these loads does not constitute a solicitation for their use, nor a recommendation.

| 6.5×55 Swedish – Above MAP 51,000 PSI |

|

| Firearm | Ruger Hawkeye African |

| Barrel Length | 24″ |

| Min – Max Case Length | 2.165″ +0.000″/-0.020″ |

| Min – Max Cartridge Overall Length | 2.750″ – 3.150″ |

| Primer | Large Rife Magnum |

| Bullet Diameter | 0.2642″ +0.000″/-0.0030″ |

| Reloading Dies | Redding |

| Bullet Type | Bullet Weight Grains |

Net H2O Grains Capacity |

COL” | Powder Type | Powder Charge Grains |

Muzzle Velocity fps |

Muzzle Energy ft/lbs |

100 Yd 3 Shot Group ” |

| Sierra Varminter | 100 | 53.7 | 2.850 | Re17 | 49.5 | 3328 | 2460 | 0.7 |

| Sierra Varminter | 100 | 53.7 | 2.850 | H414 | 49.5 | 3221 | 2304 | 0.5 |

| Sierra Varminter | 100 | 53.7 | 2.850 | Win 760 | 50.0 | 3272 | 2378 | 0.3 |

| Sierra Pro-Hunter | 120 | 53.6 | 3.000 | Re17 | 47.5 | 3113 | 2583 | 0.5 |

| Sierra Pro-Hunter | 120 | 53.6 | 3.000 | H414 | 48.0 | 3062 | 2499 | 0.8 |

| Sierra Pro-Hunter | 120 | 53.6 | 3.000 | IMR7828SSC | 51.5 | 3012 | 2418 | 0.9 |

| Nosler Partition |

125 |

52.8 | 3.025 | Re17 | 46.5 |

3039 |

2564 | 1.1 |

| Nosler Partition | 125 | 52.8 | 3.025 |

H414 |

46.5 |

2952 |

2419 | 0.7 |

| Nosler Partition | 125 | 52.8 | 3.025 |

IMR7828SSC |

51.0 |

3027 |

2544 | 0.9 |

| Hornady SP |

129 |

50.8 |

2.905 |

Re19 |

47.5 |

2854 |

2334 | 0.8 |

| Hornady SP | 129 | 50.8 | 2.905 | IMR4350 |

45.5 |

2838 |

2308 | 0.8 |

| Hornady SP | 129 | 50.8 | 2.905 | Norma 204 |

47.0 |

2771 | 2200 | 0.4 |

| Hornady SST | 140 | 47.9 | 2.905 | Re17 | 43.0 | 2855 | 2535 | 0.5 |

| Hornady SST | 140 | 47.9 | 2.905 | IMR7828 SSC | 47.0 | 2823 | 2478 | 0.8 |

| Hornady SST | 140 | 47.9 | 2.905 | Norma 204 | 45.0 | 2782 | 2407 | 0.6 |

| Hornady ELD-X | 143 | 49.5 | 3.025 | Re19 | 46.0 | 2776 | 2448 | 0.7 |

| Hornady ELD-X | 143 | 49.5 | 3.025 | IMR 7828 SSC | 48.0 | 2737 | 2378 | 0.6 |

| Hornady ELD-X | 143 | 49.3 | 3.025 | RS Magnum | 51.5 | 2744 | 2391 | 0.9 |

Email Notification