Tough year. A year of major loss and a year of counting blessings. But, you know what I mean, that’s life. We all experience the same. All you can do is work, keep busy and find those momentary distractions. Hard labor provides a great non-pharmaceutical sedative. Good people leave many good memories and good memories will get you though.

At the moment, I’m preoccupied with preparation for winter. Vehicles, snow removal equipment, auxiliary heaters, the generator, they all need to be serviced and carefully checked over. The pantry and freezer need to be stocked… Self reliance looms large.

Government engineered soaring fuel prices and diminished supply. Property taxes keeping pace with out of control inflation. Food prices demand careful shopping decisions. I am tired of living in some privileged moron’s daydream who is oblivious to the harm they are doing to others.

And then….

I was reading famous handloader magazine, a publication for gun nerds and old timers that I really enjoy. Who would not want to read, “2,016 cast bullet handloads for the 308 Winchester” or perhaps “Case annealing the 280 Ross”? And, yes, I am serious. I love those types of articles.

I was reading famous handloader magazine, a publication for gun nerds and old timers that I really enjoy. Who would not want to read, “2,016 cast bullet handloads for the 308 Winchester” or perhaps “Case annealing the 280 Ross”? And, yes, I am serious. I love those types of articles.

In any event, one of the writers stated he never found that varying bullet seating depth had an effect on pressure. Which I thought was odd as the relationship is evident, in my experience, when recording pressure data with transducer or strain gear.

I remember distinctly muttering, “Huh?”. The author is very experienced and well known and I know he has access to pressure reading equipment. And then there is every credible source of handload data that cautions against bullet substitution and altering reference overall cartridge length dimensions. Then there is Bobby Boyle…

So I decided I would try to find a method of pressure assessment any handloader could duplicate without getting into dueling test methods, test equipment and tests results.

In theory

If a firearm and cartridge are constants, if cartridge components are constant, the only way to affect a velocity change is to increase or decrease pressure.

Usually that entails altering the powder charge but, within this exercise, that must remain constant. So it is my contention, I can change velocity by reducing or increasing the internal volume of the assembled cartridge.

In search of an ideal combination to prove a point

The 45-70 Government is my favorite cartridge… Well, it is at least one of three favorite cartridges that hold a permanent presence in my gun related life. In regard to this empirical exercise, the cartridge is so flexible in bullet weight and pressure range, it is a natural for the effort.

So if the cartridge needed to be flexible, it only followed that the rifle employed would also. To that end I selected the Gray Ghost, my Ruger No. 1 with 22″ barrel, chambered for the 45-70 Gov-mint.

Most reloading manuals classify 45-70 reloading as three pressure progressions, typically represented categorically as trapdoor, followed by strong lever action, followed by the Ruger No.1 and similar. Using the Ruger No.1 permitted the use of a single rifle for all anticipated levels of loads and provide an extra margin of safety.

How strong is the Ruger No.1? One was used for developing the 358-378RG, a 35 caliber wildcat based on the full length 378 Weatherby cartridge. The one pictured is routinely used for developing full tilt 45-70 loads.

Yes, “ogive” is a word

In order to measure the effects of seating depth on pressure, using velocity as a relative +/- indicator, finding a bullet with the right shank length and ogive would allow the greatest latitude for experimenting with seating depth.

Above, an ennead of bullets, some for 45-70 levels of performance, original and modern pressure, and some intended as light bullet weights for the big .458″ magnums. Some of them are OK for use in tubular magazines, some not so much. All are OK in the single shot Ruger No.1.

Some designs are misleading in appearance. The third from the left, a GS Custom Bullet solid has a flat tip to aid penetration with the 458 Winchester Magnum and narrow driving bands to reduce bore friction.

| Bullets | Bullet Weight Grains |

Bullet OAL “ |

Minimum COAL” |

Maximum COAL” |

COAL Range “ |

| Barnes X HP | 250 | 0.895 | 2.490 | 2.535 | 0.045 |

| Remington Soft Point | 300 | 0.818 | 2.500 | 2.589 | 0.089 |

| GS Custom |

300 | 0.903 | 2.498 | 2.550 | 0.052 |

| Hornady SPRN | 350 | 0.915 | 2.470 | 2.500 | 0.030 |

| Hawk Precision SPRN |

350 | 0.875 | 2.540 | 2.590 | 0.050 |

| Speer Hot-Cor SPRN |

350 | 0.985 | 2.580 | 2.700 | 0.120 |

| Woodleigh RN | 350 | 0.955 | 2.515 | 2.616 | 0.101 |

| Swift A-Frame | 400 | 1.152 | 2.625 | 2.700 | 0.075 |

| Remington SPRN | 405 | 0.992 | 2.458 | 2.627 | 0.169 |

I was very pleased with the result. As a good number of shots fired will be required, better to tap into my metric ton inventory of inexpensive, slowly aged Remington bullets and not into my significantly less than metric ton inventory of $3 bullets.

In regional vernacular… In search of powda

IMR 4198 was selected as the powder that is to be used across all of the handloads. No, it is not optimal for all 45-70 handloads where best powder is adjusted to suit barrel length, bullet weight and velocity goals. What IMR 4198 does bring to the project is stability in full or partial loads, smooth pressure curves, good ignition properties, and an absence of compressed charges within this project.

Not exactly an upstart, IMR 4198 has been available to handloaders since the 1930s. Originally a popular choice for the 30-30 WCF, it proved to be an excellent powder for the 222 Remington, 22 Hornet and 308 Winchester. Quite a spread. A burn rate the fast side of IMR 3031, it does work well with some component combinations for the 45-70.

We care how much water weighs, because…?

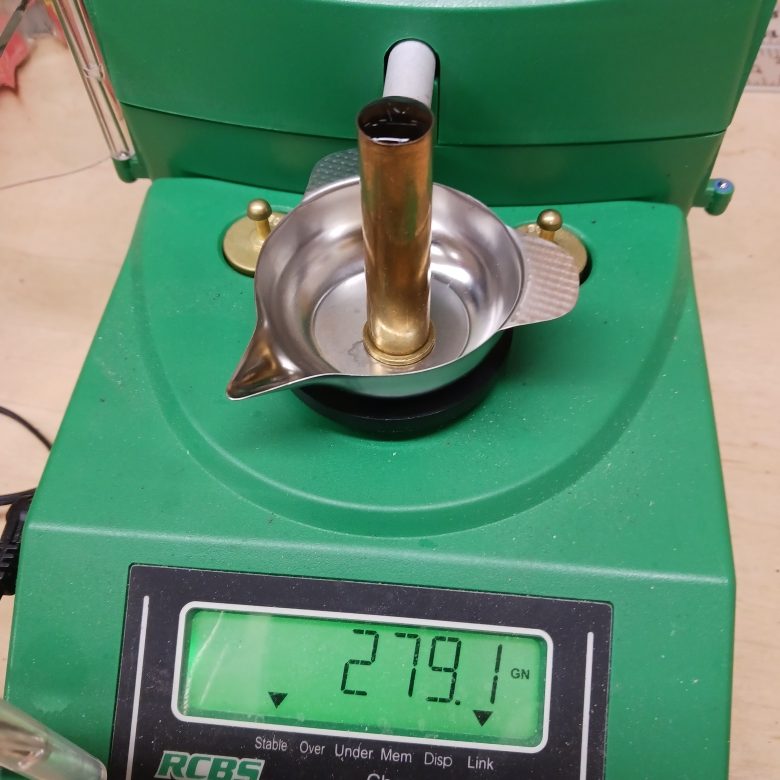

A population of once fired, full length and trimmed Starline brass was gathered. It is good quality brass, uniformly produced and cases selected for use were wet measured and sorted to within 1 tenth of a grain of H20 capacity. Cases were filled uniformly to a positive meniscus; empty weight 198.4 grains, full weight 279.1 grains, 80.7 grains of water.

Why water? Smokeless powder comes in a wide variety of size, shapes and composition. Subsequently, charge density varies so 40 grains of one type of powder may fill a case, while only 15 grains of another may do the same. Water, a non-volatile conforming fluid, is used as a universal standard for measuring comparative case capacity.

Quantitative Empirical Data… But way better than Wiki

Cartridges were assembled in a range from long enough to park the bullet on rifling to as short as the bullet shank and case mouth would allow. Through sorting and tedious, mind numbing checking, all have equal case capacity, uniform charge weight of 42 grains of IMR 4198, uniform 405 grain bullet weight, and primers as defined.

Each line of data represents and average of ten rounds. No, I am not suggesting ten rounds is statistical proof of the effects of bullet seating or bullet substitution on pressure, but I am saying this cursory look suggests a cause and effect.

| Cartridge |

45-70 Government |

| Firearm | Ruger No.1 |

| Barrel Length | 22.0″ |

| Min – Max Case Length | 2.105″ +0.0″/-0.020″ |

| Min – Max Cartridge Overall Length | 2.490″ – 2.550″ |

| Primer Size |

Large Rifle |

| Bullet Diameter | 0.4580″ +0.0″/-0.0030″ |

| Reloading Dies | Redding |

| Bullet | Bullet Type |

Bullet Grains |

Net Case Capacity H2O |

Net Cap Δ |

Primer Type |

C.O.L.” | 10 Shot Avg MV FPS |

Avg FPS Δ |

Calc PSI Δ |

| Remington | RNFP | 405 | 61.41 | – | LRM | 2.630* | 1845 | – |

– |

| Remington | RNFP | 405 | 60.79 | 0.62 | LRM | 2.615 | 1798 | -47 |

-3000 PSI |

| Remington | RNFP | 405 | 57.70 | 3.09 | LRM | 2.540** | 1835 | 37 |

2700 PSI |

| Remington | RNFP | 405 | 56.05 | 1.65 | LRM | 2.500 | 1867 | 32 |

1800 PSI |

| Remington | RNFP | 405 | 54.40 | 1.65 | LRM | 2.460 | 1882 | 15 |

800 PSI |

| Standard Versus Magnum Primers | |||||||||

| Remington | RNFP | 405 | 57.70 | 3.09 | LRM | 2.540* | 1825 | – |

– |

| Remington | RNFP | 405 | 57.70 | 3.09 | LR | 2.540* | 1834 | 9 |

-600 PSI |

| *COL increased to assure contact with rifling **Recommended cartridge overall length for bullet selected |

|||||||||

Takeaways

Bullets seated to rifling – The practice of seating a bullet out very close to or touching rifling lead dates back to a time when machining precision of freebore was not so precise and when barrel steel was more prone to throat erosion.

The idea was to move the bullet first contact beyond any oversize portions and right to the rifling. Interesting theory with the intended result of increased accuracy only provable in highly accurate benchrest type firearms.

Of greater importance is that only 0.015″ difference in COL parked the bullet on the rifling and spiked pressure for the greatest change on the table, 3000 PSI.

Overall – The amount of pressure increase was always positive as bullets were seated deeper and the net case capacity was reduced. No, the change was not proportional, pressure to depth, but pressure did lessen as bullets moved outward and increased when bullet moved inward.

Burn rate and pressure curves of smokeless powder are complex and beyond me. Some are very predictable and uniform in performance in light or heavy charges. Some powder curves flatten with full cases and maximum charges, but spike when lightly loaded. IMR 4198 was selected because of its predictability.

Primer substitution – Magnum versus standard primers was a little surprising to me. I use magnum primers a good deal, mostly for ignition assurance, and I assemble and develop charges with them in place. This choice requires further investigation and assessment.

Conclusions?

When I was in school, a professor… no, not THE professor, said that when researching we would encounter three types of sources of information. The first is the novice, who might be earnest in effort, but inexperience would lead to errors and omissions.

The second source would be the experienced provider of information who would know how to filter out suspect information and work hard to be a credible source.

The third source, the expert, in an effort to distinguish their work from others, would put a subjective spin on otherwise objective data.

Seating depth does matter in regard to control of pressure. Substitution of bullets furthers that cause and effect by introducing changes to bullet shank length and form that alter bore friction. Changes to material density and finish do more of the same. Safe spacing of bullets from rifling matters.

Nice article and experiment Joe! Very interesting read. Part of what makes handloading interesting to me is the almost endless potential variables. Then factor in figuring out what a firearm likes “best” for a given purpose. Makes for a pleasant and never ending project. Care, record keeping, and at least awareness of the metallurgy, chemistry and physics involved keeps it safe and interesting instead of “way too exciting”.

Exactly, Scott. The more elements you add, the more enjoyment you get out of it.

Joe

Interesting article. Confirmed what I have believed was the case. I use a fair amount of 4198 in my handloads for 308 Winchester and 223 Remington so you really got my attention with your choice of that powder.