I really didn’t skip town, honest. We are in the process of moving our business offices, and when they move, so moves Real Guns. Apparently, moving three doors down, or three hundred miles away takes about the same amount of effort, and results in the same amount of disruption. So, until things get back to normal in a couple of weeks, I thought I would take a few moments and update on some recent additions to the tool box.

When I work through project list, I try to make sure I have the proper tools to get the job done in a satisfactory manner. The following items were all required for various active projects, most were identified before the actual work began.

I am making some case gauges. Each gauge requires a chamber reamer, each requires pilot hole and drilling to begin the process, and lathe drilling requires a well defined center point. If you need to find center on a piece of round stock, this is a handy tool to have around, a center square. All you need to do is place the piece to be marked in the square’s “V” recess, scribe or mark a line along the square’s straight edge, then rotate the part and draw another; the intersection of the two lines is center.

This center square is sold by Micro Mark, it runs about $12.95 and handles stock up to approximately 1 3/4″ D. Micro Mark is an interesting site, and they offer a catalog of unique and useful tools at very competitive prices.

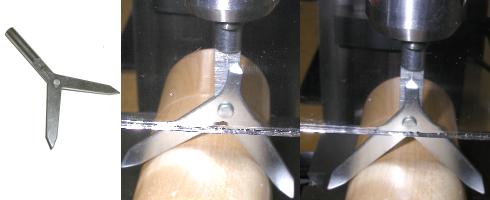

I wouldn’t go as far as using this tool to locate a metallic sights on a barrel, but it is actually very accurate when centering a drill press chuck over material with a symmetrical radius. The wings connect to a 3/8″ shank with a pivot. The idea is to move the stock or the chuck laterally until the pointer at the center of the ring points straight up and aligns with the index mark on the tool shank; pretty spiffy. I would recommend not operating the drill with the tool in place unless your intention is to remove paint or finger prints. $7.95 from Micro Mark; it will be used to locate holes in a butt stock for sling swivels.

After causing damage to my thousandth screw head, chewed up slot and bluing scraped off, it finally sunk in that I probably should pick up a set of hollow ground screw drivers and stop causing so much damage.

After causing damage to my thousandth screw head, chewed up slot and bluing scraped off, it finally sunk in that I probably should pick up a set of hollow ground screw drivers and stop causing so much damage.By the same token, after unintentionally countersinking a similar number of pressed pin holes, I thought it might be time to invest in a decent set of pin punches. I picked up a relatively inexpensive precision ground pin punch set from Brownells, #565 Starrett, that provide correct punch sizes for many firearm applications. A number of sets available from other sources contain a few useful punches, but also contain small hammers, center punches, and other miscellaneous related tools that most people would not need, or already have in their toolbox. The set’s steel punch sizes are: 1/16″, 3/32″, 1/8″, 5/32″, 3/16″, 7/32″, 1/4″, and 5/16″. The price is $35. The punch set will be used for a project that requires disassembly of a Ruger No.1.

When I set up my mini-lathe and milling machine, both had SAE threads and travel increment graduations, but virtually every attachment or accessory fastener or adjuster is metric. Since my metric Allen wrench set was down to one size, and it was seriously bent, I started checking out the Sears tool catalog for replacements. The least expensive full set was $39, and a matching set of SAE would have been the same, so I put off the purchase.

While I was wandering around in Home Depot with no specific agenda, I ran across the Husky tools version of a combo SAE/Metric Allen wrench set. The cost was $14, and it came with a peg board mountable case and built in handle for uncooperative Allen head fasteners. They come in ball and straight end versions and can be ordered online.

When I began looking for a boring head setup for my low end mini milling machine, I noticed most of the boring head set ups were about the same cost as the machine. Little Machine Shopcarries a 2″ boring head attachment that sells for $49. It utilizes 1/2″ shank boring tools and 7/8″ x 20 mount threads. Adjustment increments on the boring head are SAE. Basically, the same boring head is also available throughEnco, although Enco has an error in their online catalogue that references an incorrect mount thread and price; in reality, the Enco assembly also utilized a 7/8″ x 20 attaching thread and at the same price.

In addition to the boring head, I also needed both a 2MT and 3MT (MT=Morse Taper) shank with a 7/8″ x 20 attachment thread. Little Machine Shop had these also; $19 & $18 respectively. The final component was a set of 1/2″ shank boring tools that I purchased from Enco. They were $39 for 10 HS boring bars.

These will be used to modify bushings for my Stoney Point headspace gauge for use with .378 Weatherby based cartridges. I am also making an adapter for my inertial bullet puller for the same cartridge case that will require the same process.

This is a little something I saved, in the event my wife ever purchases, and I am ever forced to drive, an A6 Audi. I told my wife I will place this little dancer on the dashboard of the car, so everyone will know we have a “snazzy” car. Now I will finish putting together the system I started a few days ago. One of these days I’ll put together a project on buying parts and assembling Intel based computers for fun and no profit but, for now…..

Thanks

Joe

Email Notification