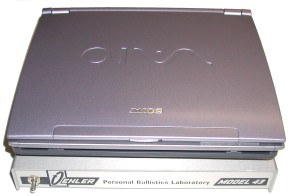

Assuming there is a valid reason for publications to always include a picture of the author with articles, I’ve decided to upgrade Real Guns and follow suit.

You can see by the look of surprise on my face, time spent with the Oehler Model 43 playing “How much pressure do my old pre 43 maximum handloads really generate?” is illuminating. Other favorite moments are spent observing the non linear progression and relationship between powder charge weight and pressure levels. What can I say, gaining knowledge can sometimes be a difficult yet somehow beautiful experience.

Short of a major investment in a universal receiver, test barrels and direct pressure transducer reading lab equipment, the Oehler product is arguably the most accurate source of pressure information for the hobby handloader. Unlike software only models that sometimes struggle with case geometry and the chore of reducing powder burn characteristics to an unrealistic prediction, a strain gauge measures the dimensional change of a barrel when a gun is fired. Based on a material standard, chamber wall thickness and brass expansion factor, strain gauge companion software reports the level of pressure required to make this measured dimensional change. The software also filters errant signals and provides a basis for analysis and record keeping.

Short of a major investment in a universal receiver, test barrels and direct pressure transducer reading lab equipment, the Oehler product is arguably the most accurate source of pressure information for the hobby handloader. Unlike software only models that sometimes struggle with case geometry and the chore of reducing powder burn characteristics to an unrealistic prediction, a strain gauge measures the dimensional change of a barrel when a gun is fired. Based on a material standard, chamber wall thickness and brass expansion factor, strain gauge companion software reports the level of pressure required to make this measured dimensional change. The software also filters errant signals and provides a basis for analysis and record keeping.

The Oehler Model 43, as with all other pressure reading methodology, is not without tradeoffs and limitations. Since a strain gauge is surface mounted to a fixed location at the midway point of a gun’s chamber length, revolvers are pretty much excluded from testing, as are slide actuated autoloaders. Rifles with short chambers and thick front receiver rings influence a barrel’s response to hoop stress and may not read accurately through a strain gauge.

The Oehler Model 43, as with all other pressure reading methodology, is not without tradeoffs and limitations. Since a strain gauge is surface mounted to a fixed location at the midway point of a gun’s chamber length, revolvers are pretty much excluded from testing, as are slide actuated autoloaders. Rifles with short chambers and thick front receiver rings influence a barrel’s response to hoop stress and may not read accurately through a strain gauge.

I’ve not had a problem with bolt action rifles and long cartridge combinations; Weatherby,Remington and Winchester rifles in magnum calibers seem to work well. Ruger No. 1 single shot rifles are excellent for use with the Model 43 but, as with all other firearms, mounting a strain gauge damages a gun’s finish, as illustrated in the photo to the left. These limitations caused me to look for alternative approaches.

The T/C Contender, particularly the G2, and the Encore offer an excellent potential for Model 43 pressure testing. The guns have no receiver ring, the barrels have little taper and some models can withstand serious pressure. When working up handloads for handgun cartridges I tend to purchase an inexpensive barrel for my Contender, mount a strain gauge under the barrel and plug away taking pressure readings. When I’m done, I put away the Contender, load up a more conventional firearm for the cartridge being developed and use the Model 43 with its proof sky screen to record accurate velocity readings. It’s been a good system.

The T/C Contender, particularly the G2, and the Encore offer an excellent potential for Model 43 pressure testing. The guns have no receiver ring, the barrels have little taper and some models can withstand serious pressure. When working up handloads for handgun cartridges I tend to purchase an inexpensive barrel for my Contender, mount a strain gauge under the barrel and plug away taking pressure readings. When I’m done, I put away the Contender, load up a more conventional firearm for the cartridge being developed and use the Model 43 with its proof sky screen to record accurate velocity readings. It’s been a good system.

When I began working on +P and Super pressure equivalent handloads for the .45 ACP, and for all the reasons I’ve just outlined wanted to use my Contender, I ran into a problem because Thompson Center does not make a standard barrel for the .45 ACP cartridge. Bummer. There are two places I am aware of that produce custom barrels for Thompson Center single shot cartridge guns; Fox Ridge Outfitters which is directly linked from the Thompson site, and E. Arthur Brown which sells custom barrels from Thompson Center as well as match grade custom barrels of their own. The past few times I’ve ordered barrels, standard or custom, I have purchased from E. Arthur Brown. Customer service is good, prices are reasonable, and there is a lot of flexibility in what they can produce.

The barrel pictured above is an “EM” series; chrome moly steel bulkl barrel, matte finish and ordered in any length between 9″ and 15″. All other required hardware; ejector and dovetailed nut plates for forearm mount is included. The barrel as described was priced at $220, scope mount and rings runs another $50. For comparison, a standard 44 Mag 14″ Contender barrel from Midway is priced at $224 and the $220 custom barrel has some other nice touches like a recessed muzzle crown and not standard chambers. Barrels can be ordered finished with a customer provided chamber reamers. E. Arthur Brown also offers an air gauged match grade barrel for about $100 more. Barrels can be ordered at an extra cost up through 24″ for the Contender, 27″ for the Encore, prices for Contender or Encore barrels are essentially the same.

The barrel pictured above is an “EM” series; chrome moly steel bulkl barrel, matte finish and ordered in any length between 9″ and 15″. All other required hardware; ejector and dovetailed nut plates for forearm mount is included. The barrel as described was priced at $220, scope mount and rings runs another $50. For comparison, a standard 44 Mag 14″ Contender barrel from Midway is priced at $224 and the $220 custom barrel has some other nice touches like a recessed muzzle crown and not standard chambers. Barrels can be ordered finished with a customer provided chamber reamers. E. Arthur Brown also offers an air gauged match grade barrel for about $100 more. Barrels can be ordered at an extra cost up through 24″ for the Contender, 27″ for the Encore, prices for Contender or Encore barrels are essentially the same.

G2 and earlier Contender barrels are frame interchangeable, and when the new barrel arrived it popped right into place including forearm. The scope bore sighted easily to the new barrel and the mount allowed a wide range of scope position adjustment. Initial test firing showed some serious accuracy potential and muzzle velocity with slow powder was appreciably higher than a 5″ auto barrel could ever generate. Now I can get back and finish my series on high pressure .45 ACP loads.

I suspect I may invest in an Encore to use for relatively inexpensive handload development for high pressure rifle cartridges. If there is any draw back to this approach, it is a barrel lead time of 8 – 12 weeks; I think this round took approximately 8, which is an eternity in dog and Real Guns years. The 17-357 RG is in lead time hell, so this is a welcome break for some activity.

07/30/04

Thanks,

Joe

Email Notification