Working on Saturday is relaxing. There are no interruptions, no distractions and I can listen to the music of my generation while I work. A couple of contemplative realizations; an online personality test concluded that my emotional age is twenty nine and playing Joni Mitchell’s “California” with the shop windows open window will call in coyotes. And back to the Ruger SR1911.

A very little cartridge background….

While the 45 Auto round is an excellent personal defense cartridge, there are times when out walking trails when a little more power could be useful. The +P offers a bit more than the standard 45 Automatic, but not significantly so. The 460 Rowland requires significant modifications to a standard 1911 type, kits are not inexpensive, a modified pistol does not work acceptably with standard 45 Auto cartridges and, even with a compensator, the round is really tough on a converted firearm.

The 45 Super cartridge can provide a meaningful boost in power to the 1911, handloading is no more difficult than the standard 45 Auto and both share common components. There are a variety of ways to configuration a 1911 type to make it work reliably and safely with the 45 Super. This will be the first modification performed on my Ruger SR1911 where no permanent modification to the pistol or its piece parts is required. There are several installments dedicated to this conversion process and, because this represents experimenting with the SR 1911, I’d suggest reading the series through to the end to see how it all turns out. I do not know what the concluding configuration is at this time and won’t know until I have everything sorted.

I always thought that the 45 Super was the best 1911 cartridge that almost was. In commercial form, the 45 Super is essentially a 45 Auto round operating above 45 Auto and 45 Auto +P Maximum Average Pressure levels, while maintaining all external dimensions of the 45 Auto cartridge. In 1988, Dean Grennell modified 30-06 Springfield brass, or 308 Winchester brass and finally .451 Detonics Magnum brass by trimming it to 45 Auto length, then loaded ammunition to approximately 39,000 PSI to deliver performance well in excess of the 45 Auto +P. Yikes!

Hindman Custom 45’s, Inc. of Kerrville, TX refined Grennell’s concept by reducing the cartridge’s maximum pressure ceiling to 29,000 PSI, which eliminated the need for 451 Detonics brass. Hindman’s shop also modified 1911 type pistols to to function reliably and safely at this pressure level. The Hindman derivative cartridge was named and trademarked .45 Super in 1997 1). While the physical cartridge and performance criteria were open to duplication, use of the 45 Super name was not and this arguably dampened interest in the concept and further development. In any event, the trademark was canceled in 2008 and there is nothing that prevents anyone from using the name or working with the concept.

Today, the process of getting to the 45 Super, ammunition and firearms, is a bit less involved. Starline Brass produces 45 Super headstamped brass that is thicker in the web than the 45 Auto or +P case and is made from more dense material. Quality premium 1911 pistols like the Ruger SR 1911 are supplied with features that were once considered gunsmith refinements and there are a number of solutions to address hyper slide dynamics.

Pictured left to right, with measurement of web thickness: 45 Auto 0.187″, 45 Auto +P 0.187″, 45 Super 0.201″, 460 Rowland 0.187″. Interesting as the 460 Rowland case, a cartridge that operates at approximately 40,000 PSI. Is 45 Super brass required to load to 45 Super pressure levels? Certainly not where the chamber offers full support, but it is never a good idea to use incorrectly headstamped brass that might lead to high pressure ammo finding its way into the wrong firearms. Based on the Super’s thicker web, it would seem charges would need to be adjusted downward to accommodate a reduction in case capacity. More on this later, but not so. While the horizontal web is thicker, the case wall taper is thinner with the result that case capacity is the same for 45 Auto and 45 Super. I do use 45 Super brass for Super level loads to lessen the chance they will find their way into a firearms configured for standard 45 Auto ammo.

| Cartridge | MAP KPSI |

Bullet Weight Grains |

Standard MV FPS |

ME Ft-Lbs |

| 45 Auto | 21 | 185 | 995 | 407 |

| 45 Auto +P | 23 | 185 | 1130 | 525 |

| 45 Super® | 29 | 185 | 1300 | 694 |

| 45 Auto | 21 | 230 | 915 | 428 |

| 45 Auto +P | 23 | 230 | 975 | 486 |

| 45 Super® | 29 | 230 | 1,100 | 618 |

The table illustrates the differences within the indicated group of cartridges.There is no SAAMI standard for 200 grain 45 Auto or 45 Auto +P performance so no comparative entry was made. The universal receiver test barrel used to achieve indicated velocities is 5″ with a 1:16″ twist.

The 45 Super may not bring much to self defense as penetration and wound channel are more than sufficient with the 45 Auto and 45 Auto +P against a human assailant. For hunting, or as a trail gun or survival weapon, the increase in performance is significant at point of impact and the 45 Super offers improved trajectory.

All that follows is personal experimentation and not a definitive set of instructions as there are many mechanical differences within a population of 1911 types. As an example, Ruger tends to more heavily spring their SR1911s than many other 1911 type manufacturers. Ruger went with an 18 Lb recoils spring and 30 Lb mainspring as compared to other manufacturers who install a 16 Lb recoil spring and a 23 Lb mainspring. Subsequently, I may select a recoil spring rate that is lighter than suitable on another manufacturer’s product because the high mainspring rate increases hammer resistance to slide movement.

My apologies to Ruger for having my way with their product in ways they never intended. Within that organization there are many talented technical people with a wealth of experience that made decisions as to how the SR 1911 was define and constructed. It is common for people outside of that environment to make judgements based on what they believe, which may not represent the entire picture. Subsequently, this is just a record of my efforts and not a recommendation for others.

It is with these understandings…

There is an odd passage in “The M1911 Complete Owner’s Guide” by Walt Kuleck page 233 regarding the influence of the pistol’s mainspring on recoil spring selection which concludes with, in paraphrase, “…before juggling springs it may be a good idea to leave the pistol true to John Browning’s design”. The passage was odd for several reasons: it appears in a book that is dedicated to modifying the 1911, John Browning’s patent design did not specify spring rates and manufacturers have always tailored mainspring and recoil spring rates to barrel/slide length and type of ammunition anticipated. My Colt Gold Cup National Match was supplied with a 16 Lb recoil spring and 23 Lb mainspring. A Kimber set up for 45 Super received a 28 Lb recoil spring. The Ruger SR1911, both 45 Auto and 10mm Auto versions, ship with an 18 Lb recoil spring and 30 Lb mainspring. For my own firearms, recoil springs are changed to suit ammunition to protect them from being damaged by elevated slide velocity and to make them function reliably.

In any event, it is always helpful to have good reference materials handy to serve as a foundation when performing maintenance or planning modifications. Kuleck’s “The M1911 Complete Owner’s Guide” and Kulek and Oldham’s “The M1911 Complete Assembly Guide, Kuhnhausen’s “The Colt 45 Automatic – A Shop Manual Volume I” and “The U.S. M1911/M1911AI & Commercial M1911 Type Pistols – A Shop Manual Volume 11” are all good sources of information.

Try, try try again….

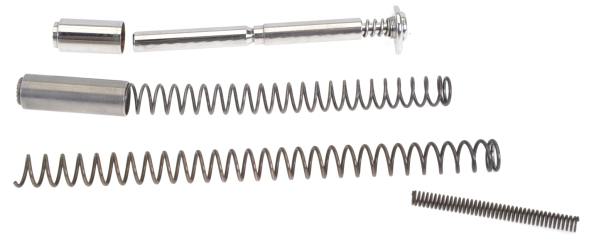

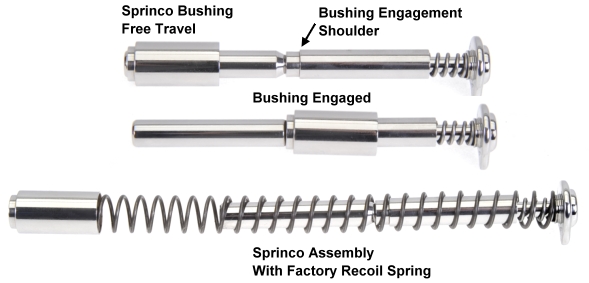

From top to bottom in picture above: Sprinco Recoil Management Guide Rod System (Cor-Bon) #11074, factory 18 Lb recoil spring and plug and 24 Lb Wolff recoil spring with extra power firing pin spring. My experience with the Sprinco system and the 45 Super level ammunition has been good. What does that mean? They typically plop into place, are matched up with the factory standard recoil spring and work as advertised. As pictured below, the Sprinco unit provides a secondary recoil spring resistance. The primary recoil spring controls slide movement until the Sprinco bushing engages the guide rod’s shoulder and begins to compress the guide rod’s spring. The secondary spring does not begin to compress and resist slide movement until the pistol’s hammer is back and mainspring resistance is not present. For the first part of slide rearward travel, resistance is from recoil spring and mainspring. The second part of slide travel sees resistance from the recoil spring and the Sprinco guide rod spring. Slide racking effort is hefty, but not unmanageable.

In this case, after installation, the pistol worked without a hitch with standard velocity 230 grain ammo and it did not chuck ejected Super loads into the next county. No sign of slide or frame or barrel link lug hammering. The pistol cycled reliably and locked open on empty. Empties fell into an area approximately eight to ten feet away… a brisk toss.

A couple of problems developed with the Sprinco unit installed. When the pistol was locked open on empty, it took two hands tugging on the slide to allow the slide stop to rotate down and release the slide. Additionally, signs of the firing pin tip peening over primer strike indentations suggested early unlock. So while I scratched my head to think how best to alleviate both conditions, I replaced the Ruger factory 18 lb spring with a 28 Lb recoil spring, the type installed on Colt Delta Elite 10mm pistols and the same I have used with other Super conversions. This combination proved too heavy when coupled with the 30 Lb Ruger mainspring.

A couple of problems developed with the Sprinco unit installed. When the pistol was locked open on empty, it took two hands tugging on the slide to allow the slide stop to rotate down and release the slide. Additionally, signs of the firing pin tip peening over primer strike indentations suggested early unlock. So while I scratched my head to think how best to alleviate both conditions, I replaced the Ruger factory 18 lb spring with a 28 Lb recoil spring, the type installed on Colt Delta Elite 10mm pistols and the same I have used with other Super conversions. This combination proved too heavy when coupled with the 30 Lb Ruger mainspring.

In search of a better solution, a 24 Lb recoil spring was used in place of the Sprinco set up, installed with an extra heavy firing pin spring. The pistol cycled reliably with Super level ammo, locked open on empty and a sharp tug released the slide. Empties were deposited six to ten feet away from the pistol and no more smudged primers. Remaining issue? Excess effort required to rack slide. Issue to be revisited.

Handload preliminaries…

Since the casing marked 45 Super has a thicker web as verified by cutaway and direct measurement, it would seem to follow that the case has a lesser capacity than a standard 45 Auto case… but not really. When checking case capacity, a food preparation hypodermic without needle makes quick work of filling cases, especially bottle neck cases that like to hold onto air bubbles. The eyedropper does a good job of topping off while avoiding an excessive negative or positive meniscus. The modeling clay is basically whatever color my granddaughter does not like. Cases need to be thoroughly cleaned after checking as non hardening clay containes petroleum products that can ruin primers. Water is distilled for consistent weight, stored in the same physical area where checking occurs.

The capacity checking process – An empty case is weighed, then it is filled with water and weighed. The water full case weight becomes the minuend, the empty case weigh becomes the subtrahend and the difference is the case capacity expressed as whole and tenth grains. The 45 Auto cases checked an average of 26.3 grains, the 45 Super checked an average of 26.6 grains and that is what was used as nominal capacity for the 45 Super case during load development. Yes, that is correct. The 45 Super case had a slightly greater capacity even with the thicker horizontal web, because the case wall is thinner.

Bullet selection; but maybe that’s just me…

Left to right – The 185 grain coated bullet is an Acme hard cast. Good penetration, relatively high velocity and good accuracy. Next, 185 grain Remington Golden Saber which is good for defense against a human adversary or for hunting thin skilled game where exceptional penetration is not desired. The Golden Saber expands properly, without fragmenting, over a wide velocity range. The 225 grain hard cast is a good trail load that will penetrate deeply, hold together and not fragment even on heavy bodied game. The 240 grain Sierra Sports Master is on the heavy weight end of the 45 Auto spectrum and originally designed for vintage and modern 45 Colt handguns. Sierra indicates the bullet will properly and full expand for hunting applications in cartridges from the 45 Auto and up through 1,400 fps muzzle velocity in concert with the 454 Casull which makes it a good bullet for 45 Super level applications.

| Bullet | Bullet Type |

Bullet Weight Grains |

Bullet Length “ |

Cartridge Overall Length “ |

| Acme Hard Cast |

Lead SWC | 185 | 0.603 | 1.255 |

| Remington GS |

JHP | 185 | 0.535 | 1.245 |

| Acme Hard Cast |

Lead FN | 225 | 0.616 | 1.210 |

| Sierra Sports Master |

JHC | 240 | 0.643 | 1.185 |

A precautionary tale…

Warning: The handloads on the table below approximate the pressure levels typically assigned to the 45 Super, 29,000 PSI. This is in excess of the 45 Automatic 21,000 PSI and the 45 Automatic +P 23,000 PSI. The 45 Super is a proprietary cartridge without a published specification and without homologation under SAAMI or CIP. Subsequently, I would refer to the following data as 45 Super level and dimension handloads. If you are not familiar with working with these types of less than well documented cartridges and processes, I would suggest not attempting. If you are, I would suggest backing off the data below by 5% and working up as required and desired.

| 45 Super – For use only in appropriately modified firearms | |

| Firearm: Modified Ruger SR1911 |

Barrel Length: 5″ |

| Bullet Diameter: 0.4520″ -0.0030″/+0.0″ Jacketed Bullet Diameter: 0.4530″ -0.0030″/+0.0″ Lead |

Primer: Large Pistol CCI #300 |

| Case Length: 0.898″ -0.010″/+0.0″ | COL Min – Max: 1.190″ – 1.275″ |

| COL and Capacity | Load Data & Performance | |||||||||

| Bullet | Type | Bullet Weight Grains |

C.O.L. Inches | Net Grains Water | Powder | Charge Grains | MV FPS | ME Ft/Lbs | 25 Yd 3 Shot Group ” |

|

| Acme Hard Cast |

SWC | 185 | 1.255 | 17.1 | Power Pistol |

10.8 | 1307 | 702 | 1.8 | |

| Remington Golden Saber | JHP | 185 | 1.245 | 19.2 | Power Pistol | 11.0 | 1323 | 719 | 2.1 | |

| Acme Hard Cast | FN | 225 | 1.210 | 14.4 | Power Point | 9.0 | 1138 | 647 | 1.9 |

|

| Sierra SportMaster | JHC | 240 | 1.185 | 12.7 | Power Pistol | 9.0 | 1104 | 650 | 1.6 |

|

| Groups shot from a rest |

||||||||||

And the music goes round and round and it comes out here…. metaphorically speaking. Power Pistol was selected because it allows a wide charge range, it is as pressure predictable at 80% fill as it is at 105%, it ignites and burns with standard large pistol primers, and it is easy to meter in its flake form. I am using up Acme coated 185 grain cast bullets and switching to traditionally lubed bullets from the same company, only because I can’t see a performance benefit and the 75¢ per hundred saved isn’t worth the added handling in reloading. The coating gets in my dies and shaved onto case mouths.

Loading Golden Saber and Acme lubed cast was uneventful, except seating both resulted in slightly compressed charges. The Sierra bullet has a cannelure that is not used in conjunction with the 45 Auto round. The COL noted on the table puts the cannelure ever so slightly below the case mouth, which puts a taper crimp on solid footing. The 1.185″ COL is a Sierra reloading manual number. It is actually 0.005″ under the SAAMI minimum, but I have experienced no feed problems with this ogive and COL.

Concluding thoughts…

The Ruger configuration works handling 45 Super level roads as modified, but more finesse is needed and that will come in Part III. The objectives of Part III are an easier to rack slide, no coil bind, reasonable ejection, and no early unlock. I think I have a working solution, but I need to run it for a while more to be convinced.

Email Notification