The basis for this continuing Ruger SR 1911 project is strictly an opportunity to work with a firearm of personal interest. Work on the prior two 45 Super installments led to spending some time with spring combinations, with the hope a more balanced configuration could be found… an exercise in following the bread crumbs to see what develops.

After experimenting with a few hundred rounds of 45 Super, 45 Auto and 45 Auto +P level loads as combination of springs was found that provided appropriate slide management, both cycling as an auto loader and manually racking. The Sprinco unit was set aside as as having excess compressed length; the pistol compressed the Sprinco unit to the point of being coil bound, or near coil bound, causing the slide to not reliably lock open on empty or requiring a ridiculous amount of effort to release the slide when it did lock open on empty. Yes, it would not be a major rework to correct the problem, but the focus was the pistol and the Sprinco piece was not a necessity.

After experimenting with a few hundred rounds of 45 Super, 45 Auto and 45 Auto +P level loads as combination of springs was found that provided appropriate slide management, both cycling as an auto loader and manually racking. The Sprinco unit was set aside as as having excess compressed length; the pistol compressed the Sprinco unit to the point of being coil bound, or near coil bound, causing the slide to not reliably lock open on empty or requiring a ridiculous amount of effort to release the slide when it did lock open on empty. Yes, it would not be a major rework to correct the problem, but the focus was the pistol and the Sprinco piece was not a necessity.

A 26 Lb recoil spring and 23 Lb mainspring were used for 45 Super loads and a 16 Lb recoil spring and 23 Lb mainspring were used for 45 Auto standard and +P level loads. Racking effort was higher than Ruger factory springing in the Super configuration, but the slide locked open on empty and released with reasonable effort. The factory spring rates for the SR1911 45 Auto and 10mm Auto pistols are 18 Lb recoil and 30 Lb mainspring. For the sake of context, Colt 1911 45 Auto spring rates are 16 Lbs for recoil and 23 Lbs for mainspring. The reduction in spring rate reduced slide racking effort and trigger pull. As a result of the mainspring rate reduction, 2 Oz were dropped from trigger pull, 5 lbs 3 Oz to 5 Lbs 1 Oz. Not an earth shaking change, but some, and generally a change made for reduce trigger pull.

For anyone wanting to experiment with spring juggling, as opposed to machete or bowling ball juggling, Wolff Springs offers mainsprings as; reduced power #s 18, 19, 20, 21. Wolff’s factory replacement #s is 23 and extra power are available in #s 25, 26, 28, and 30. Wolff recoil springs are available as; reduced power #s 11, 12, 13, 14 and 15. Factory is rated at 16 lbs and extra power #s as: 18.5, 20, 22 and 24. My 26 Lbs and 28 Lb spring came from Wolff’s Colt 1911 10mm Auto Delta listing.

Too heavy of a recoil spring can cause short stroking slides, stove pipe jams and failure to feed or cycle. Too light will smack the crap out of the stop pin and barrel link lug, allow premature unlock, cause bulged cases, etc. It is the cliche etcetera that is probably the greatest concern. Too heavy of a hammer spring can contribute to high racking effort and increase trigger pull to a relatively minor degree, too light can cause misfires and/or a need to increase recoil spring rate for proper slide movement control. Reduction in mainspring rate will lighten trigger pull to a minor degree. As an example, dropping the Ruger’s a mainspring from 30 lbs to 23 lbs reduced trigger pull by only 2 Oz.

Changing a mainspring…

Springs can be quite hazardous if not managed properly. I have had my share of upward ejecting recoil spring plugs, but I have gotten to the point where I can hold out my hand without looking away from the work, and catch the part on reentry. One time I was pulling the front coil springs out of my ’67 Mustang using cheap J hook compression tools. One J hook decided it had held on long enough and proceeded to rotate about the outside of the spring, using my index finger, backed by a coil, as a final stop. The tip of my finger burst spraying blood everywhere, including along the way to the emergency room. What does this have to do with the 1911? Nothing. It’s just that I never felt my wife provided adequate sympathy, something about “You don’t know pain until you’ve given birth, whiner” so I find myself still seeking sympathy from strangers.

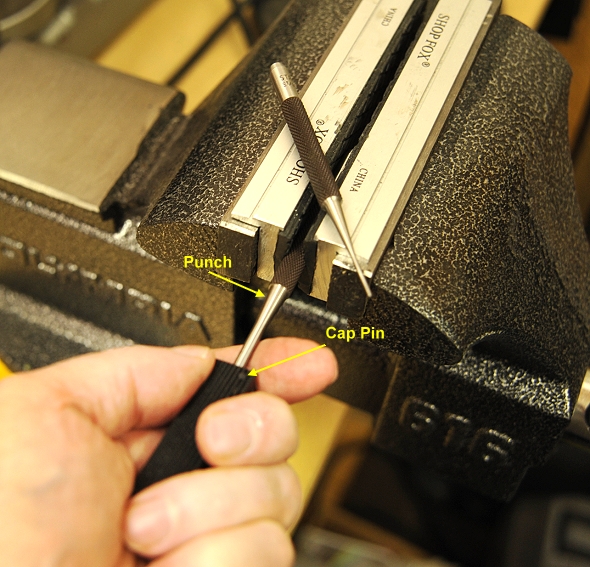

This is what I like to refer to as a multifaceted informational image, or “MI2” if you will. To begin at the beginning, the pistol’s magazine is pulled, the chamber is cleared and the hammer is lowered to remove preload from the mainspring. With frame and grip supported, a punch is used to drive the mainspring housing pin left to right until the pin is free of the frame. Always drive the pin left to right and reinsert the same or people in gun forums will hold you up to ridicule unless, of course, you are located in the southern hemisphere. In that cause you should drive the pin left to right. A little rhyme I remember to make sure I get this right; “Inert, and drive out, the mainspring housing pin from the left side so that the punch is striking a self centering concave pin surface and the the convex surface of the other pin end will guide it into the mainspring housing and lift the tip of the mainspring housing pin retainer so it can unlock/lock as applicable in the pin’s center groove”.

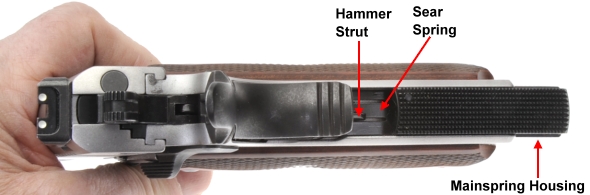

While the mainspring housing appears to be a small lump of inert steel or plastic, in the case of the Ruger it is steel, it is actually home to significant parts typically found in a 1911. Getting them to come out to facilitate a hammer spring change is easy. The Wolff mainspring free length is longer than the Ruger mainspring, but installed high where spring rates are determined is the same. The wire stock is about the same diameter, but the diameter of the spring is slightly smaller and the material is processed to a different temper. If you get them mixed on the bench the Wolff spring has a distinctive bronze cast as compared to the black Ruger spring.

The pin retainer under even static mainspring loading protrudes into the pin and holds it in place. The mainspring stores energy against the mainspring cap, which drives the hammer strut/hammer when it is clears the sear. The cap pin holds it all together as a self contained assembly.

To disassemble the mainspring cap needs to be slightly compressed to unload the cap pin and allow its removal. The effort asserted in minor, but you tend to run out of hands before you run out of parts that need to be under control. I’ve done this by placing a small ball bearing on the top of the cap and compressing it with a clamp, but the use of a vise to hold a punch is probably easier.

Yes, I realize the picture is a little blurry, but this is my fun project so I am not moved to re-shoot it. Basically, a punch that will fit in the mainspring housing and clear the cap pin is secured in padded vise jaws, strike side in. The housing is held in hand, grip surface up with the hand closed under the cap pin so the pin will be caught when it falls out…. to avoid having to crawl around on the floor to find it after it falls out. The housing is pushed against the punch, the pin is unloaded and either falls out or is pushed out with punch two sitting atop the vise. Pressure is then eased off the spring, keeping in mind the housing is full of little parts… so tipping up is a good idea.

The springs are swapped, then the process is reversed with two notations. The first is that the punch/vise thing is done with the mainspring’s grip surface down. The pin is hat shaped and needs to drop in from the backside. The second is that care must be taken to make sure the sear spring isn’t bumped or allowed to move out of position and that the tip of the hammer strut is centered in the mainspring cup as the housing is slipped into position.

Yes, most 1911 bench blocks have a recess and dowel that is used to disassemble mainspring housings. Unfortunately, I always come up one hand short when using this approach.

Where to?

With the 45 Super out of my system for a bit, the pistol is going to be stripped and each of the systems reworked. The objective is to: make the slide feel as though it is running on ball bearings, finessing the trigger so that it breaks like a thin piece of glass, upgrade the sights so they stand out like traffic lights against the target and, finally, install a nice set of grips.

Email Notification