![]() Not directly related to this week’s column “SIG or Colt ?”, but I wanted to take a moment to thank Dave Davison over at CH/4D for being able to do what no other reloading equipment supplier has been able to do for the past 8 weeks, provide next day delivery on a set of reloading dies for the Weatherby factory .338-378 cartridge.

Not directly related to this week’s column “SIG or Colt ?”, but I wanted to take a moment to thank Dave Davison over at CH/4D for being able to do what no other reloading equipment supplier has been able to do for the past 8 weeks, provide next day delivery on a set of reloading dies for the Weatherby factory .338-378 cartridge.

While sets for this specific cartridge are listed in RCBS and Redding literature as available at extra cost (in the case of RCBS – available from stock at extra cost), this appears to be the equivalent of what the software industry use to call “vaporware”, or product that was created by a marketing department, and never actually saw the light of day in production.

RCBS accepts order for these dies with, “Can’t believe I have none in inventory”, then puts them on eternal backlog. I know, I waited the committed 6 – 8 weeks, with zero progress in delivery status, before canceling. I also ended up canceling a set of standard .357 SIG dies from RCBS when these headed into 5 weeks with no delivery. I picked these up in one day from another supply source. Great at providing presses and accessories, damn poor at providing dies. When I tried to order .338-378 dies from Redding, at least they were honest enough to tell me they had never actually received the reamers to make the die set, and spared me a needless wait.

If you’re not aware, CH/4D represents the 1990 merger between CH Tool & die, a company founded in 1947 by Charles Heckman, and 4D Custom Die Co., founded in 1985 by David Davison and Dawna Davison. Quite an operation. It was a nice change of pace to get quick turn around on e-mail tech questions, then at the end of the exchange, have a variety of die sets to choose from. In this case I was able to select a .001 resize at the neck and .0005 resize on the body, for cases fired in my own rifle. I get a perfect fit for my gun’s chamber, I won’t have to overwork cases as a result of unnecessary resizing, and I get a little extra case capacity. The dies are standard thread 7/8 x 14, so they fit virtually any bench mounted reloading press, and they took about 2 minutes to set up.

The CH/4D site is still under partial construction, but check out the online catalog. If you’re a reloader, and working with anything from a .17-221 to a .50 BMG, bet you’ll find whatever you’re looking for. How about a set of dies for your pet 30 Belted Newton, or maybe that special 20mm Vulcan you’ve been planning on taking out for chucks ? There is, of course, a full line of very heavy duty reloading presses, power case trimmers, powder dispensers, Bullet Swaging Dies, etc. Even if you’re not looking for anything at the moment, this site is like a history of wildcat cartridges and performance cartridges, and an education in hardcore reloading.

I think I’m going to see about getting sets of Titanium Nitride (TiN) Coated dies for my volume bottle neck cartridge loads, like the .357 SIG. Looks like a nice CH/4D solution to the absence of carbide dies for this type of ammo. Anyway, another article, another time. Thanks again Dave.

SIG or Colt ?….. Sometimes you just have to move on.

More and more, brands like Glock and SIG are crowding gun magazine pages, taking coverage away from traditional brands like Colt and Smith & Wesson. They are filling purchase orders placed by law enforcement, as well as filling display cases at local retailers. In support of these increased sales, catalogs from suppliers like Brownells, have more and more pages dedicated to accessories for these firearms. Obviously guns for serious use, they fly in stark technical contrast to the 1911 guys, who are trying to keep a single action auto tradition alive.

I owe my introduction to SIG, to….well, Colt. When Colt began it’s public platform of anti gun ownership politics, and started donating money to help elect anti-gun candidates around the country, I had to accept the reality that Colt was no longer being run by people who appreciated firearms based sports, or the people who bought their products. It became painfully obvious that Colt would form an alliance with anyone who could grease the skids for more government contracts, even if it meant an end to individuals owning firearms. As a long term customer, I exercised my only option, I stopped buying anything produced by Colt.

To tell you the truth, it wasn’t that big of a decision. Under the current ownership, Colt turned its production into plastic and pot metal replicas of the real guns they use to make. Compounding this problem, Colt also implemented the worst customer service function possible, to preside over what must be a sea of defective product returns. As an alternative to Colt, I looked at 1911 type guns from: Baer, Kimber, Wilson, Para-Ordnance, and S & W. Some shot really well, very accurate, but none really offered more than I already had in my existing .45’s. Then I read about the SIG 229, looked at the ballistics for the .357 SIG, and thought I’d take a closer look.

The P229 actually feels very much like my Colt Officers Model. The Colt has been worked over quite a bit and, while being a little slab sided, has a wide beavertail grip safety, and a mag funnel that extends the grip downward. The P229, originally designed for high capacity, staggered row ammo storage, has wider grips. But when you grab on, the pressure on your hand, thumb and fingers feels the same as the Colt. Even the contour of the upper portion of the grip, where the gun presses against the web of your thumb, feels the same.

The P229 actually feels very much like my Colt Officers Model. The Colt has been worked over quite a bit and, while being a little slab sided, has a wide beavertail grip safety, and a mag funnel that extends the grip downward. The P229, originally designed for high capacity, staggered row ammo storage, has wider grips. But when you grab on, the pressure on your hand, thumb and fingers feels the same as the Colt. Even the contour of the upper portion of the grip, where the gun presses against the web of your thumb, feels the same.

Oddly enough, I’ve heard people categorize the SIG’s length of trigger pull and trigger location as being too long for people with small or average size hands. I say “oddly” because, in single action, the distance from the rear of the grip to the trigger is a quarter inch shorter than the Colt. I can’t comment on the SIG’s double action pull, I rarely use it. The reach to the front of the trigger guard is almost a half inch longer on the SIG, which leaves my left thumb in an unfamiliar positioned.

My Colts are chambered for the .45 auto. My SIG has barrels for both the .357 SIG and the .40 S&W, with a changeover taking less than a minute. Barrel length for both guns is pretty close, 3.5″ for the Colt and 3.8 for the SIG. This slight difference is proportionally reflected in the length of the SIG’s slide. Even so, the SIG with fixed sights, and the Colt with Millet adjustable sights, have an identical 5.7 inch sight radius.

My Colts are chambered for the .45 auto. My SIG has barrels for both the .357 SIG and the .40 S&W, with a changeover taking less than a minute. Barrel length for both guns is pretty close, 3.5″ for the Colt and 3.8 for the SIG. This slight difference is proportionally reflected in the length of the SIG’s slide. Even so, the SIG with fixed sights, and the Colt with Millet adjustable sights, have an identical 5.7 inch sight radius.

The Colt carries it’s weight at the grip, the SIG seems a little more muzzle heavy. The trigger on the Colt has been worked on, and breaks cleanly at less than 4 lbs. with no creep or rough spots. The SIG trigger, as received from the factory, requires a lot of motion to fire (in both double and single action) and is a little rough. It is still much better than the Colt, as received from the factory but,eventually, I’ll have it smoothed out. The stainless Colt weighs 34 oz., while the SIG, with its stainless slide and aluminum alloy frame, weighs 27.5 oz.

Both guns seem to have the potential to shoot with the same degree of accuracy, regardless barrel selection for the SIG. This leads me to believe that the limiting factor in accuracy is the shooter rather than the guns. When I’m having a respectable shooting day, all will group under 1.25″ at 50′ with a two hand hold. On a not so good day, I can do that at 25 feet. On rare occasions, I’ve gone half that group size at both distances, but none have been as accurate as my longer barreled Gold Cup. Not sure how well the long barrel P229S would do under similar circumstances. Despite the short barrels of both the Colt and SIG, keeping the front sight on the target with relatively rapid fire is pretty easy.

Both guns seem to have the potential to shoot with the same degree of accuracy, regardless barrel selection for the SIG. This leads me to believe that the limiting factor in accuracy is the shooter rather than the guns. When I’m having a respectable shooting day, all will group under 1.25″ at 50′ with a two hand hold. On a not so good day, I can do that at 25 feet. On rare occasions, I’ve gone half that group size at both distances, but none have been as accurate as my longer barreled Gold Cup. Not sure how well the long barrel P229S would do under similar circumstances. Despite the short barrels of both the Colt and SIG, keeping the front sight on the target with relatively rapid fire is pretty easy.

The path required to get to this similarity in feel and shooting was dramatically different between the two brands of guns. My Colt Officers Model was assembled with many poorly manufactured parts, it broke frequently, and for a long period of time was extremely unreliable. By comparison, and a sign of Colt’s deterioration, the Gold Cup Colt I purchased over 15 years ago, which has been fired many more times than the Officers model, is in the exact same configuration it was in when received from the factory. The Gold Cup remains failure free, required no mods and is still extremely accurate. So far, the SIG is performing in a similar fashion.

The path required to get to this similarity in feel and shooting was dramatically different between the two brands of guns. My Colt Officers Model was assembled with many poorly manufactured parts, it broke frequently, and for a long period of time was extremely unreliable. By comparison, and a sign of Colt’s deterioration, the Gold Cup Colt I purchased over 15 years ago, which has been fired many more times than the Officers model, is in the exact same configuration it was in when received from the factory. The Gold Cup remains failure free, required no mods and is still extremely accurate. So far, the SIG is performing in a similar fashion.

My assessment, after my experience with this small Colt, and several other recently manufactured units, is that current Colt production is just junk. Only a company with little respect for its customers would ship expensive guns with plastic triggers, plastic mainspring housings and cheap cast irregular finished trigger parts. It goes beyond acceptable cost reduction, when parts you would expect to find in a $200 gun make their way into guns costing 3 to 4 times as much. And the quality problem at Colt is not limited to their lower end models, if there is such a thing as a low priced Colt.

It took a lot of parts from specialty manufacturers to get the Officers Model fitted with a decent trigger and to get it to feed, extract and eject reliably. Today the gun will feed and fire just about anything I want to load into it, from target loads to high speed hollow points. Unfortunately, including the initial cost of the gun, it cost over $1,400 to get the gun to this point. I am not looking forward to balancing sets of springs to make the gun continue to work with new loads, or worrying about worn barrel bushings and loose slide fit, both which will eventually have a significant, negative impact on accuracy.

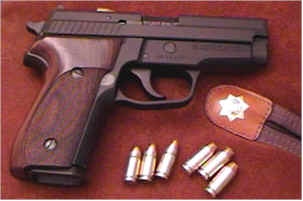

The SIG on the other hand, at well below half the cost, has been pretty much there, as received – and devoid of the little design problems that plague most 1911 style pistols. The gun is not a work of art, but it is a good, reliable working piece. I always know it will fire and feed when I pull the trigger. No wrestling with one piece guide rod takedown, in fact, it only takes about 30 seconds to remove the top assembly and swap barrels. I did buy an extra barrel so I could shoot .40 S&W and the .357 SIG, but I really have no practical excuse for doing so, the .357 is a better round for virtually everything. I did buy factory walnut grips, because I can’t stand the cheesy plastic grips that are standard, anymore than I liked the lame rubber grips that shipped with the Colt.

The SIG on the other hand, at well below half the cost, has been pretty much there, as received – and devoid of the little design problems that plague most 1911 style pistols. The gun is not a work of art, but it is a good, reliable working piece. I always know it will fire and feed when I pull the trigger. No wrestling with one piece guide rod takedown, in fact, it only takes about 30 seconds to remove the top assembly and swap barrels. I did buy an extra barrel so I could shoot .40 S&W and the .357 SIG, but I really have no practical excuse for doing so, the .357 is a better round for virtually everything. I did buy factory walnut grips, because I can’t stand the cheesy plastic grips that are standard, anymore than I liked the lame rubber grips that shipped with the Colt.

I don’t like the standard rear sights on the SIG (right), Eventually, I will get the $39 rear sight (far left) to convert the gun to a three dot system, or the front/rear night site option. The standard ball on a stick set is okay, but loses side reference in dim lighting. After that I’ll buy…humm…nothing….that’s all there is. Like I said, out of the box, it’s a pretty complete gun.

I don’t like the standard rear sights on the SIG (right), Eventually, I will get the $39 rear sight (far left) to convert the gun to a three dot system, or the front/rear night site option. The standard ball on a stick set is okay, but loses side reference in dim lighting. After that I’ll buy…humm…nothing….that’s all there is. Like I said, out of the box, it’s a pretty complete gun.

Another major difference between the Colt and the SIG, is the difference they express in handgun cartridge philosophy. I always liked the .45 auto round. The bullets are heavy and large in diameter. The guns that shoot them are loud and have heavy recoil. When I was a kid, I use to feel the same way about the .30/30, until I was finally convinced to try the high speed, smaller bore .243 or .25/06. Power is a function of velocity and mass, when expansion and penetration are properly managed by bullet design. Nothing, that comes 30 to the pound, is going to bowl anything over when moving at a slow speed, which makes the .357 SIG, in comparison to the .45 auto, a significantly fast step in the right direction.

The short barreled Colt Officers Model will move a .45 caliber 185 grain Gold Dot, with a sectional density of .130, at slightly over 800 fps, and yield around 260 ft./lbs. of muzzle energy. The shooter pays a penalty in recoil of about 10 lbs. The sectional density equivalent slug in the .357, 115 grains, leaves the short barreled SIG at almost 1500 fps, with over 530 ft/lbs. of energy and about 8 lbs. of recoil, – twice the power with 20% less recoil. I know that for most of us believe handgun rounds fall off the face of the earth after 25 yards, but for reference, the SIG drops 3″ at 100 yards, the .45 about twice that amount. High levels of performance, in relatively short barreled autos, is one of the great benefits of the .357 SIG.

So what I think I have here in the P229 SIG, is a more modern firearm that has addressed many of the weaknesses of the older Colt design, a more refined manufacturing process to produce the guns as quality product, and a major improvement with a modern round that seems to have a lot in common with the ancient .30 caliber Luger. I think the .40 S&W version of the SIG is more of a security blanket, offered by SIG to fill a safe space between the .45 auto and the .357. The .40 looks like a small .45, but bigger than the 9 MM that was frequently criticized for being under powdered, yet not a controversial departure from the norm as the bottle neck .357.

I’m not sure why data for the .357 SIG is so sparse in hardcover reloading manuals. It seems component and equipment suppliers are not very quick to pick up “new” cartridges, even when they have been out for more than a few years. But on request, several component companies will provide loading data and the Internet offers quite a bit of reloading data on sites like Alliant’s interactive reloading manual.

I’m not sure why data for the .357 SIG is so sparse in hardcover reloading manuals. It seems component and equipment suppliers are not very quick to pick up “new” cartridges, even when they have been out for more than a few years. But on request, several component companies will provide loading data and the Internet offers quite a bit of reloading data on sites like Alliant’s interactive reloading manual.

More pistols are appearing chambered for this round, including several Glock models. Numerous ammo manufacturers are producing loaded ammo for defense and target shooting and, recently, retail outlets seem to have an extensive selection on hand. I had no problem locating a set of dies and a Gold Dot seating plug from a retail supplier. The required shell plate was the same as that used for the .40 S&W.

Many of the articles written regarding reloading the .357 SIG, suggest the round is difficult to work with , requires special handling, or is an oddball cartridge. In one very recent issue of a national magazine, the author wrote of the .357 SIG, “It’s like a .40 S & W, only it’s really a 9 MM. not .357, but the case is different cause if you make brass from .40’s, they’ll be .020″ short, but that seems to be okay. Only this isn’t a round for a novice to work with, if you use a bullet that is too short, it will fall in the case, doubt if this round will survive as it’s only 150 fps faster than…..”.

I think it’s time to accept that the .40 and .357 are two different cartridges, and the fact that they share case head dimensions isn’t exactly story fodder for the Twilight Zone. There are many cartridges that share case head dimensions, but that does not mean all can be used interchangeably when reloading. The bottle neck design, and subsequent absence of carbide dies, means the .357 SIG must be handled just like every other bottle necked cartridge, cases cleaned and lubed. I have no idea why, at this late date, anyone would address loading the .357 SIG as an experimental process. The following represents some of my observations from my first experience in working with this cartridge.

The .357 SIG (R) pictured next to a .40 S&W that has been run through a.357 resizing die. It was easy to form, but came out approximately .015″ shorter than an actual .357. I have seen some articles indicating the SIG headspaces on the neck and, others, at the case mouth. For now I’ll assume that missing .015″ is important, and avoid using resized .40 brass in my SIG. At the least, less area to grip the bullet can’t be good in an autoloader and, with a short overall cartridge length and deep bullet seating, this missing material could be critical. Think I’ll write that down somewhere, “Make sure when you reload for a pistol or rifle that you only use dimensionally correct brass”.

The .357 SIG (R) pictured next to a .40 S&W that has been run through a.357 resizing die. It was easy to form, but came out approximately .015″ shorter than an actual .357. I have seen some articles indicating the SIG headspaces on the neck and, others, at the case mouth. For now I’ll assume that missing .015″ is important, and avoid using resized .40 brass in my SIG. At the least, less area to grip the bullet can’t be good in an autoloader and, with a short overall cartridge length and deep bullet seating, this missing material could be critical. Think I’ll write that down somewhere, “Make sure when you reload for a pistol or rifle that you only use dimensionally correct brass”.

I picked a 115 grain load, right off the Alliant web site. I tend to reload light-medium to medium weight bullets in my guns, 155 gr in .40s and 185 gr in .45s. I like the inherent higher velocity, and not using bullet weights that kick the crap out of the gun and my shooting hand.

I picked a 115 grain load, right off the Alliant web site. I tend to reload light-medium to medium weight bullets in my guns, 155 gr in .40s and 185 gr in .45s. I like the inherent higher velocity, and not using bullet weights that kick the crap out of the gun and my shooting hand.

In addition, with all of the process precautionary comments I had seen in articles, I wanted to pick a load that might bring to light any problems associated with this round. The sharply curved ogive of the 115 grain Gold Dot leaves only an abbreviated shank for the case to grip. The 1.150 overall cartridge length could have made getting a grip even more difficult. None of these issues actually surfaced as a problem during the reloading process.

Once again, the .357 SIG is a bottle necked case. Die sets contain two dies, sizing and seating, and they are not carbide. The absence of this hard, smooth surface means cases need to be well cleaned and lightly lubed before they enter the sizing die – easily accomplished with a quick roll across the lube pad.

Once again, the .357 SIG is a bottle necked case. Die sets contain two dies, sizing and seating, and they are not carbide. The absence of this hard, smooth surface means cases need to be well cleaned and lightly lubed before they enter the sizing die – easily accomplished with a quick roll across the lube pad.

I made sure the brass was tumbled clean, primer pockets wire brushed and necks did

I made sure the brass was tumbled clean, primer pockets wire brushed and necks did  not have any powder residue build up. I really try to avoid interior case neck lube unless absolutely necessary. These are all steps I would have gone through reloaded any cartridge.

not have any powder residue build up. I really try to avoid interior case neck lube unless absolutely necessary. These are all steps I would have gone through reloaded any cartridge.

Unlike 3 piece die sets that run an expander into the case mouth and bell the opening to make starting a new bullet an easy process, bottle neck cartridge get expanded from the return motion of the expander ball that is affixed to the decapping pin. The result is that the case neck is kept to a much closer tolerance, compared to bullet size, so case necks must be kept cleaned and correctly formed. This is a good place to use a hand held inside outside neck case reamer to make sure there aren’t any burrs or nicks that may interfere with bullet seating.

Unlike 3 piece die sets that run an expander into the case mouth and bell the opening to make starting a new bullet an easy process, bottle neck cartridge get expanded from the return motion of the expander ball that is affixed to the decapping pin. The result is that the case neck is kept to a much closer tolerance, compared to bullet size, so case necks must be kept cleaned and correctly formed. This is a good place to use a hand held inside outside neck case reamer to make sure there aren’t any burrs or nicks that may interfere with bullet seating.

I wanted to use Alliant Power Pistol Powder (boy, say that three times fast) because it seems to generate higher performance with lower operating pressures. Unfortunately, it was unavailable locally. I moved down the list to Blue Dot, which would also work with several other cartridges I’ll be reloading.

I wanted to use Alliant Power Pistol Powder (boy, say that three times fast) because it seems to generate higher performance with lower operating pressures. Unfortunately, it was unavailable locally. I moved down the list to Blue Dot, which would also work with several other cartridges I’ll be reloading.

You may be able to see that the powder charge pretty much fills the case right up to the base of the neck. There is minor compression when the bullet is seated. The max charge listed on the Alliant site was 11.3 grains and was the highest pressure of any loads listed for the .357 SIG. As typical for working up a load, I did not use the max load as a starting point, but backed off approx. 10% and incremented by approx. .2 grains, each 10 rounds, until I worked my way up to the max load.

The die plate really looks vacant with the two piece die set. The black “die” in the rear with the white ring is a powder checker. It basically detects when you have thrown a high, low or no powder charge before the case rotates to the bullet seating position. It’s a nice reminder and better than watching the drop tube.

The die plate really looks vacant with the two piece die set. The black “die” in the rear with the white ring is a powder checker. It basically detects when you have thrown a high, low or no powder charge before the case rotates to the bullet seating position. It’s a nice reminder and better than watching the drop tube.

Every 10th round coming off the powder measure station was scale checked, and every 10th completed round was checked for overall length. All rounds were inspected for proper primer seating, dings and nicks in cases.

Every 10th round coming off the powder measure station was scale checked, and every 10th completed round was checked for overall length. All rounds were inspected for proper primer seating, dings and nicks in cases.

Couple of lessons I’ve learned rather quickly. If the press feels odd in any way, something is wrong. Stop and look until you find what caused the change. If you find an error on the complete bin. like a light load, an out of spec round length, or a partially seated primer, check  everything. If you have doubts about powder throws and suspect there might be some light or heavy loads, get out the puller and disassemble everything that is questionable. The exercise will cause you to pay greater attention, next time. You never know what you’ll find during an inspection like this.

everything. If you have doubts about powder throws and suspect there might be some light or heavy loads, get out the puller and disassemble everything that is questionable. The exercise will cause you to pay greater attention, next time. You never know what you’ll find during an inspection like this.

Since I started this overall reloading project, after sorting through a variety of combinations, I’ve been able to select a few loads for the volume cartridges I shoot. This is only for this point in time, and I will add to the list over the next few months. These are for reference only. If you are interested in trying them, they need to be sourced from their original documentation in the Hornady and Speer reloading manuals, as well as on the Alliant web site.

Cartridge: SIG .357

Cartridge: SIG .357

Powder: Alliant Blue Dot

Charge weight: 11.3 grains

Bullet: Speer 9 MM Gold Dot JHP

Bullet weight: 115 grains

Primer: CCI 500

MV as listed: 1495 fps 4″ barrel Note: Light recoil, very tight groups

Cartridge: .40 S&W

Cartridge: .40 S&W

Powder: Alliant Unique

Charge weight: 8.0 grains

Bullet: Hornady XTP

Bullet weight: 155 grains

Primer: CCI 500

MV as listed: 1200 fps 4″ barrel Note: Light recoil, good grouping

Cartridge: .45 Auto

Cartridge: .45 Auto

Powder: Alliant Unique

Charge weight: 7.3 grains

Bullet: Speer Gold Dot

Bullet weight: 185 grains

Primer: CCI 300

MV as listed: 900 fps 5″ barrel Note: Very accurate Officers and GC

In conclusion, handguns are going through a major revolution. When revolvers were generally pushed aside by autoloaders in volume sales, practical cartridges were no longer limited to straight cartridge case walls. The stage was set for innovation, and further mainstream movement into the world of more powerful, high velocity rounds. Some manufacturers, like SIG, have already started to take advantage of this opportunity, others will follow. Numerous articles have appeared covering high speed .22 caliber centerfire auto pistols, and many more will follow. The .357 SIG, the .400 Cor-Bon, the BOZ…..

Think how few practical cartridge choices there are today when selecting a mainstream handgun. Compare that to the broad selection of cartridges available for rifles, where successful new rounds enter the market every year. High performance autoloaders, from quality manufacturers who don’t mind reinvesting a portion of profits into R&D efforts, will be the market leaders of tomorrow. I think I can see the future of handguns, I just can’t see Colt. So why did I bother with a listing for the .45 auto ? Sometimes it just takes a while to move on completely.

Thanks

Joe

Email Notification